Introduction

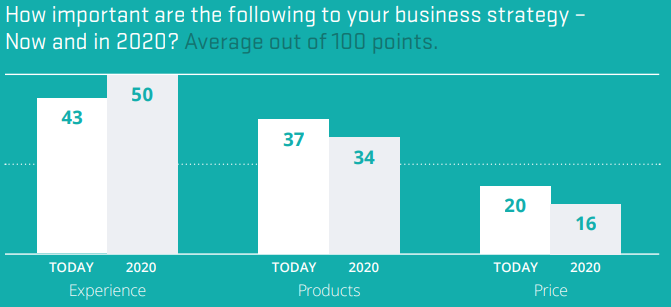

Across industries from retail to healthcare, customers expect a flawless, highly personalized experience whenever they interact with a company. According to a recent study, customer experience has overtaken product and price as the main way businesses differentiate themselves. A positive customer experience can build lasting loyalty but today’s consumers are more fickle than ever, and won’t hesitate to switch to a competitor if they’re dissatisfied. New technologies are powering all of these customer experiences—from point-of-sale machines that enable self-checkout in a retail store to interactive kiosks for patient check-in at a medical clinic.

All tech companies are in the service business

As technology transforms how companies interact with customers, field service organizations face particular challenges in adapting their business models to meet rising customer expectations. The need for skilled technicians to deploy and maintain the technology

required to create engaging customer experiences has never been greater. At the same time, companies are challenged to find new ways to cost-effectively source the talent they need in the tightest labor market in decades, with unemployment at a 50-year low. Workers in skilled trades such as electricians and HVAC technicians, along with IT staff, have the most in-demand skills in today’s labor market. Original equipment manufacturers (OEMs) of the technology products facilitating self-service customer experiences face a competitive global market with intense margin pressure. As a result, many manufacturers now provide services to supplement their traditional product offerings and generate an ongoing revenue stream beyond the initial device purchase. These OEMs have traditionally been “pure-play” service providers focused solely on service offerings for the products they manufacture. But, this dynamic is changing as customers prefer a “one-stop shop” for services across all of the product lines they have deployed. Contracting with value-added resellers (VARs), third-party maintainers (TPMs) and managed service providers (MSPs) is an increasingly popular way for companies to source field-service talent because these providers act as a single source for all services. In addition, they typically deliver these services at a lower total cost to end customers than multiple service contracts with OEMs because of their leaner cost structure. While established market categories exist for manufacturers and service providers, the lines between these companies are blurring, and many manufacturers now offer a combination of hardware and services to their customers.

Evolution of the field service labor market

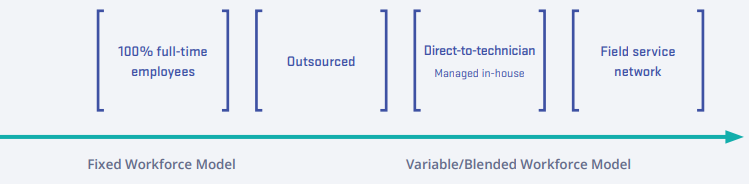

Traditional Model: 100% full-time employees

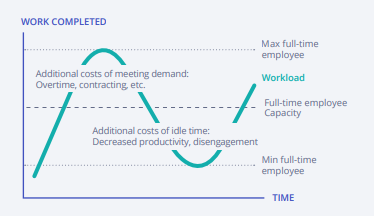

The traditional field service staffing model—used by end customers, OEMs and service providers alike—includes hiring full-time employees with specific skill sets. This model of 100% full-time employees has high fixed costs, particularly given the rising cost of health insurance, training costs, and other employee benefits. In addition, the field service industry’s evolution from fixed-price agreements to event-based pricing makes it difficult to anticipate revenue and plan appropriate staffing levels. With increased uncertainty in revenue, companies risk over-hiring staff and diluting their profit margins. Furthermore, the larger a company becomes, the more difficult it is to optimize employee utilization. For example, if a company has 900 workers in the field, it would be nearly impossible to keep all 900 employees working 40 hours a week consistently due to fluctuations in demand for different skills and different projects. In addition, the company would have to pay overtime to cover spikes in work. The traditional staffing model also limits growth. Today’s customer experience-driven industries require a wide variety of specialized technical skills. However, OEMs and service companies typically focus on one segment of the market and hire accordingly. For example, a manufacturer of printers and copiers generally hires technicians who can service printers and copiers. They do not have the in-house expertise to service a customer that needs assistance with a networking project, and will miss that revenue opportunity. Customers want a one-stop-shop for service across their technology portfolio, yet it is nearly impossible for manufacturers and service companies to deliver all of the specialization required using 100% fulltime employees. Furthermore, the traditional model does not allow service businesses to keep up with seasonal spikes in demand, which is another lost opportunity for companies using an inflexible staffing model.

Outsourced Model

During the Great Recession, many companies began outsourcing their field service function to third-party service businesses in response to market pressure to shrink their full-time workforce. In addition to cost reduction, the outsourced model allowed these companies to focus on their core business, rather than managing a large field services organization. Field service outsourcing was popular for many years and offered several advantages over the traditional fixed staffing model. However, its limitations also became clear as many companies encountered issues over the quality

of service delivery, and sought more visibility and control over work outcomes.

Direct to technician: Preferred vendor networks (managed in-house)

In the past several years, the field service industry moved away from both the 100% full-time employee and 100% outsourced models. The modern approach to field service staffing has evolved toward using a blend of full-time and contingent labor. This trend takes advantage of the emerging “Gig Economy” and the growing number of self-employed technicians that organizations use to complement their full-time employee base. The direct-to-technician model gives companies more control over quality of delivery while allowing them to reduce costs, typically by 30 to 40 percent over full-time workers. Initially, companies have begun using this approach by creating and maintaining their own preferred contractor networks. While a direct-to-technician model is attractive from a cost and flexibility standpoint, a “do-it-yourself” approach is far more complex and potentially risky than it may appear on the surface. This model generally requires a dedicated vendor management team to handle the complexity involved with managing hundreds, or even thousands, of field service contractors. From a technology standpoint, do-it-yourself solutions quickly become outdated, are difficult to maintain and are cumbersome to integrate with other tools.

In this model, the hiring company is responsible for:

- Sourcing: company recruits its own workers through networking, job boards, LinkedIn or other methods.

- Managing work: hiring company assigns the right worker to the right job and ensure all SLAs are met.

- Managing workers: hiring company is responsible for onboarding, training, credentialing, issuing 1099s, filing payroll taxes in all applicable states, paying contractors and procuring insurance.

Platform-enabled, direct-to-technician model

A new workforce model has recently emerged that gives companies the cost advantages of a direct-to-technician approach without the complexity of managing a contingent workforce. Used by both OEMs and third-party service providers, the platform-enabled, direct-to-technician model improves both the efficiency and quality of service delivery.

This model provides the benefits of a network of pre-qualified technicians and access to a platform that offloads the complexities of contractor management, including:

- Sourcing: Platforms continuously curate technicians based on a realtime rating system so that customers can connect with the top tier of service professionals nationwide. Companies have access to field service professionals with a variety of specialized skills and certifications, saving recruiting time and minimizing the risk of hiring someone that is not qualified to do a particular job. In addition, matching algorithms help identify top talent quickly, and reviews provide access to feedback from companies that have worked with technicians in the past.

- Managing work: Platforms provide visibility into in-flight work so dispatchers can manage any work orders that are at risk. They also track project budget against actual spend and provide pricing insights to attract the right workers with standard pricing in their area.

- Managing workers: The platform-enabled approach automatically handles issuing 1099 forms, filing taxes and paying contractors.

- Streamlining workforce onboarding: Curating a list of well-prepared technicians requires some work upfront when adopting a platform, but platforms, by necessity, offer services and technology designed to train technicians on how to successfully use their product. Furthermore, because technicians are increasing platform workload, they are incentivized to do the work accurately or risk future jobs. Platforms also allow clients to add their own employees or third-party vendors so that they benefit from the efficiency the platform provides across all talent types in the organization.

Choosing a field service network and platform

New platform-enabled, field service communities are emerging in response to the market need for cost-efficient, high-quality field service talent. Here are a few essential qualities to look for:

- Number of technicians

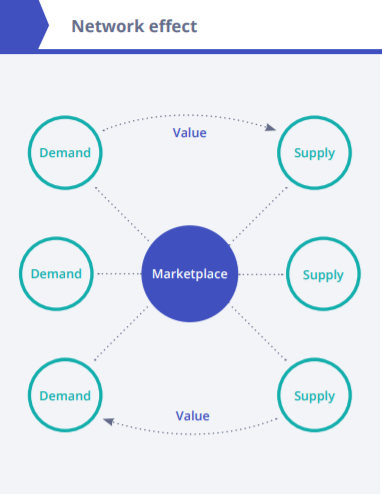

Look for a network with more than 10,000 members and expertise in the specialized skills you need. Like social networks, these field service networks take advantage of

a powerful “network effect.” As new technicians join the network, more value is created for all of the hiring companies looking for field service talent. Likewise, as more field service jobs are posted, the more technicians can benefit from being part of the network. Thus, the network with the most critical mass will provide the most value for all. - Fill time

Fill time, or the time required to assign a technician to a job should be measured in minutes. Leading platform-enabled communities have average fill times of 8 minutes or less, whereas finding technicians on craigslist, Indeed, Monster or other job boards can take hours. - Service level agreement (SLA) compliance

Look for an SLA compliance rate of 99%+. This is one of the ways to ensure consistency and quality of the technician base. - Fault rating

Fault rating represents how often a technician causes a problem on the job and is a key measure of marketplace quality. Leading platforms have less than .02% at-fault rating by including pre-qualified technicians who will complete work correctly the first time, and weeding out ineffective providers.

Conclusion

Access to specialized contingent labor — combined with a platform that takes the complexity out of managing a blended workforce—makes it possible to fulfill customer demand in a way that would be time- and cost-prohibitive with other staffing methods. Using a platform-enabled field service network, companies can optimize the cost and quality of their field service workforce while setting themselves up for growth.