The field service landscape is more complex than it’s been in decades. Sticky service inflation, shifting customer expectations, and continued supply chain instability force service leaders to adapt.

Many companies are extending the life of existing equipment and turning to break/fix support more frequently to minimize downtime and disruptions. This shift allows service organizations to make break/fix a dependable, scalable part of their business.

Market trends driving break/fix demand

Extended asset life has become the new reality in field services, with equipment refresh cycles stretching to 5 to 7+ years. Companies are deliberately postponing hardware refreshes in response to short-term budget constraints and rising concerns around tariffs.

This trend has been building for some time, as equipment becomes more modular and upgradeable, and as cloud infrastructure reduces the wear on on-premises devices.

Break/fix work provides a steady flow of service opportunities. While other types of field service work can be highly seasonal, repairs remain steady year-round, especially as more organizations focus on maintaining aging assets instead of replacing them.

Placeholder graphic for inspiration

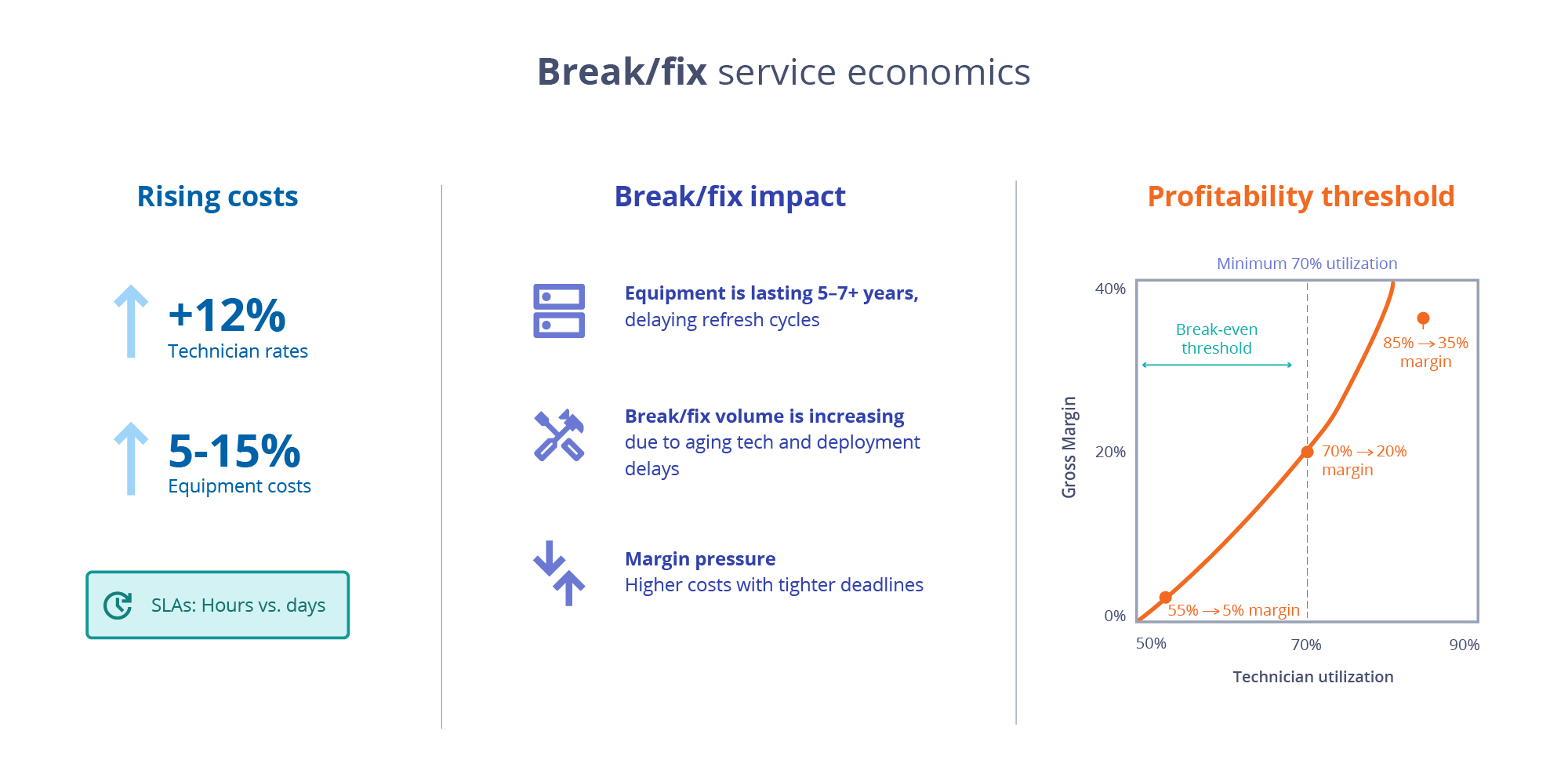

But steady work doesn’t necessarily mean steady margins, as service delivery costs continue to climb:

- Hourly rates for field service technicians have increased 12% or more year over year

- Equipment costs have increased 5-15%, with some estimates as high as 35%

- SLAs are tightening, with response times now measured in hours versus days as business dependence on technology intensifies

The result? Greater pressure on service providers to deliver efficiently.

Break/fix work is reactive, but your process shouldn’t be

Break/fix work often moves fast. Tight SLAs, quick turnarounds, and shifting schedules can leave little room for error. When the right systems aren’t in place, it’s easy for small gaps to create bigger headaches. Common challenges include:

- Work orders that lack key details or consistency

- Delays in assigning jobs or approving completed work

- Communication missteps that lead to confusion on-site

- Unclear expectations for parts logistics or documentation

But here’s the good news: with the right structure and support, these issues are preventable. A well-run break/fix program can bring predictability and performance to even the most time-sensitive repairs.

Boost technician utilization with break/fix work

Maximizing your workforce’s efficiency is critical to keeping pace with rising costs. When analyzing productivity metrics using marketplace data, we’ve discovered a significant opportunity: break/fix work can strategically boost overall technician utilization rates. On-demand break/fix work brings operational flexibility that helps smooth technician workloads across fluctuating project demands.

Here’s why that matters: A drop in utilization has an exponential impact on gross margin.

- At 85% utilization, gross margin is typically around 35%

- At 60% utilization, gross margin drops dramatically to just 10%

Our analysis shows that profitability suffers significantly when technician utilization falls below 75%. This is where on-demand break/fix work provides a valuable solution. It can fill gaps in technician schedules and maintain higher utilization rates to preserve margins.

Turn break/fix into a strategic advantage

When the right systems are in place, break/fix work becomes more predictable and easier to scale. With clear processes, consistent communication, and the right technician support, you’re in a better position to deliver, no matter what the market throws your way.

Ready to strengthen your break/fix approach? Contact our team to explore what’s possible.